Recently, in a conversation with a fruit nursery they said that “they have a fifth-generation greenhouse.” To my surprise, how can this be as these greenhouses are not suitable for nurseries, the answer was “well, they do have modern greenhouses.”

It occurred to me that clarifications are badly need regarding classification of greenhouses and I hope that this blog at EastFruit will help with that.

What are fifth generation greenhouses, why and who really needs them?

The division of industrial greenhouses into “generations” was introduced about ten years ago by the Russian company Fito (now LIS) to promote so-called semi-closed greenhouses on the market. Currently, this division is used by greenhouse specialists in Russia and other post-Soviet republics, but is largely unknown in other countries.

All over the world, greenhouses are divided according to various criteria. The main critera to describe a greenouse are the following:

● Self-designed or industrially designed and manufactured.

● By type of cover – glass or plastic (various films or polycarbonate).

● By design – free-standing (tunnel) or multispan, (Venlo-type).

● By heating – solar heating or with additional heating (using boilers running on different types of fuel).

● According to the heating system – air (using air hoses) or water (using a pipe system).

● With or without the use of artificial supplementary lighting (litted).

● By technological level – low or high tech greenhouses.

The boundary between high and low technologies is quite blurred, since, if desired, individual elements of high tech (drip irrigation, microclimate sensors, hydroponics, air humidification, etc.) can be used in a greenhouse that is quite simple in design.

To make profits investors needs to build and designe greenhouse with the goal of providing optimal conditions for growing of a particular botanical species (or group of species) of plants. It is not going to be a profitable investment decision to build a greenhouse for growing cucumbers, only to convert it a few years later into growing cut roses. It is more rational to immediately decide what will be grown and in what time frame, and design a greenhouse specifically for this purpose.

Excellent example of such investment is a Canadian grower Houweling’s Tomatoes. At the end of the last century they decided to build a greenhouse that would not be exposed to pests from outside, so that the need to use pesticides could be avoided. Together with the Dutch company Kubo, a greenhouse manufacturer, the concept was created. After that, they constructed the greenhouse called Ultra Clima. In such a greenhouse there are almost no ventilation windows, and a slightly increased air pressure is maintained inside, so insects simply physically cannot get inside (they are pushed out by the air). Windows are needed only to regulate the air pressure inside.

With the windows practically closed in the Ultra Clima greenhouse, the air quickly heats up. Thus, to avoid overheating of the plants, a rather complex system was designed for taking in external air, mixing it with internal air to the required temperature and humidity, and distributing it through air ducts under gutters with plants throughout the greenhouse. During the operation of the first semi-closed greenhouse, it turned out that this design can significantly reduce energy costs. In a modern greenhouse, energy is spent not only on maintaining the air temperature, but also on drying or humidifying it at certain periods, that is, on creating a microclimate as a whole. It is no coincidence that modern greenhouses are called controlled environment agriculture (CEA).

In order to explain the differences between semi-closed greenhouses and others, the Fito company proposed dividing greenhouses into “generations” as follows. The first category included solar-heated tunnel type greenhouses.

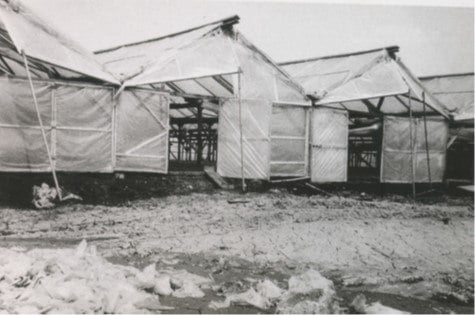

First generation greenhouse

The second includes glazed greenhouses for year-round use.

Second generation greenhouse, the greenhouses in the photo are already half a century old, they are no longer used all year round, but they are still in operation.

The third is the so-called “anthracite” (named after the city where the structures were manufactured in Ukraine, which was part of the USSR). These were greenhouses copied from Dutch Venlo blocks of the seventies, now there are almost none left. The height of the greenhouses in the ridge reached 4 m; plants were grown mainly in the ground.

The third generation or the so-called “anthracite”, there are fewer and fewer of them left, it is very expensive to heat

The fourth generation includes modern high (6-7 m) Venlo greenhouses, named after the city in the Netherlands where such type of greenhouses first appeared, which use computer control and management of microclimate parameters, shading and energy-saving screens, hydroponics… Currently, this is the most common type of high-tech industrial greenhouse in the Northern Hemisphere. In this case, the coating material is not important; they can be either glazed or film.

Fourth generation greenhouse

The fifth generation was called semi-closed greenhouses. To date, in addition to Ultra Clima, about a dozen different concepts of semi-closed greenhouses are used in the world. Semi-closed greenhouses can significantly reduce energy costs and the need for protective measures, resulting in increased productivity and product safety.

Fifth generation greenhouse

However, investments in semi-closed greenhouses are significantly higher (about twice) than in conventional modern greenhouses. In recent years investment costs have increased even more due to rising prices for metal structures, glass and film. Such greenhouses are very effective for growing cucumbers, tomatoes, peppers, and eggplants. There have been attempts to garden strawberries in such greenhouses, but they have not become widespread as this crop has a relatively low yield.

In nurseries and organic farms, where plants are grown on the floor, on tables or in the ground, semi-closed greenhouses are not suitable, since there is either nowhere to place air ducts or they interfere with the operation of equipment.

During the operation of semi-closed greenhouses, it turned out that agronomists need to learn to use new technical capabilities, since the microclimate conditions in them differ significantly from conventional high-tech greenhouses of the so called fourth generation. Over the past twenty years Dutch scientists have developed the whole concept of Growing in a New Way (Het Nieuwe Telen). It was created for semi-closed greenhouses, but it turned out that its principles are quite applicable in ordinary modern greenhouses and can significantly reduce energy costs.

Relatively recently, heat recovery systems appeared on the market. They also mix warm and humid indoor air with cold and dry outdoor air and distribute the conditioned air through film sleeves. However, such systems are much cheaper than semi-closed greenhouses and can be built into existing greenhouses while semi-closed greenhouses must be built from scratch. These systems can significantly reduce energy costs, but require the agronomist to take a different approach to cultivation – the aforementioned Growing in a New Way.

Is the highest technology or “fifth-gen greenhouses” needed everywhere?

The experience of Central Asia shows that in their climatic conditions in ordinary high-tech greenhouses it is not possible to obtain such harvest as in temperate countries. A greenhouse, which in Ukraine or Moldova allows you to get at least 50 kg of tomato per square meter without artificial additional lighting, in Uzbekistan or Tajikistan will only yield 25-30 kg/m2. It is not just due to the lack of natural light in winter – the heat in midsummer causes big problems as well. The problem of overheating can be partially solved by pad-and-fan cooling.

Fourth generation greenhouse. Pad-and-fan cooling

On one side of the greenhouse, honeycomb panels are mounted on the wall, which are constantly moistened. Supply fans on this side of the greenhouse and exhaust fans on the opposite side ensure constant movement of outside – hot and dry – air through the panels and further along the rows of plants. The water evaporates, the air cools, so the air temperature in the greenhouse is lower than outside. Yes, the temperature field inside the greenhouse is less uniform than in semi-closed greenhouses, but the investment is significantly lower. Such greenhouses operate successfully in many countries with hot climates, including Spain and Uzbekistan.

Another reason for crop shortages is pests and diseases, especially viruses, but this can be solved by improving the skills of agronomists and greenhouse owners.

In Western European countries, Moldova and Ukraine, a sharp rise in energy prices in the 2022/2023 season forced owners of modern high-tech greenhouses to abandon year-round cultivation of vegetables and take a break for the winter. Yes, such a solution leads to a decrease in overall production volumes and market oversaturation during certain periods, but it significantly reduces energy consumption and production costs.

This modern greenhouse proves that the division into generations is very arbitrary. It would seem that it should be classified as the first generation, but many elements of high technology are quite applicable in it, it is suitable for vegetables and berry crops, and for nurseries, it all depends on how and what to fill it with.

In Moldova and Ukraine there are many low-tech greenhouses that are used only from spring to autumn. Such greenhouses require solar heating, but allow the production of cheap products that successfully compete with high-tech greenhouses in the summer. One of their advantages is the ability to grow a wide range of crops and quickly adapt depending on demand. In a high-tech greenhouse built for growing cucumbers, the transition to growing lettuce will require significant reconstruction and new investments. The main problem of low-tech farms is the high labor cost per unit of output and the difficulty of finding enough labor in the season when everyone needs people for picking.

It is as a result of the growing labor shortage and increasing energy prices that the technological level of greenhouses will only increase over time, but at the same time the professional level of agronomists and greenhouse owners must also increase. Otherwise the investment will not pay off.

The use of the site materials is free if there is a direct and open for search engines hyperlink to a specific publication of the East-Fruit.com website.